DESCRIPTION

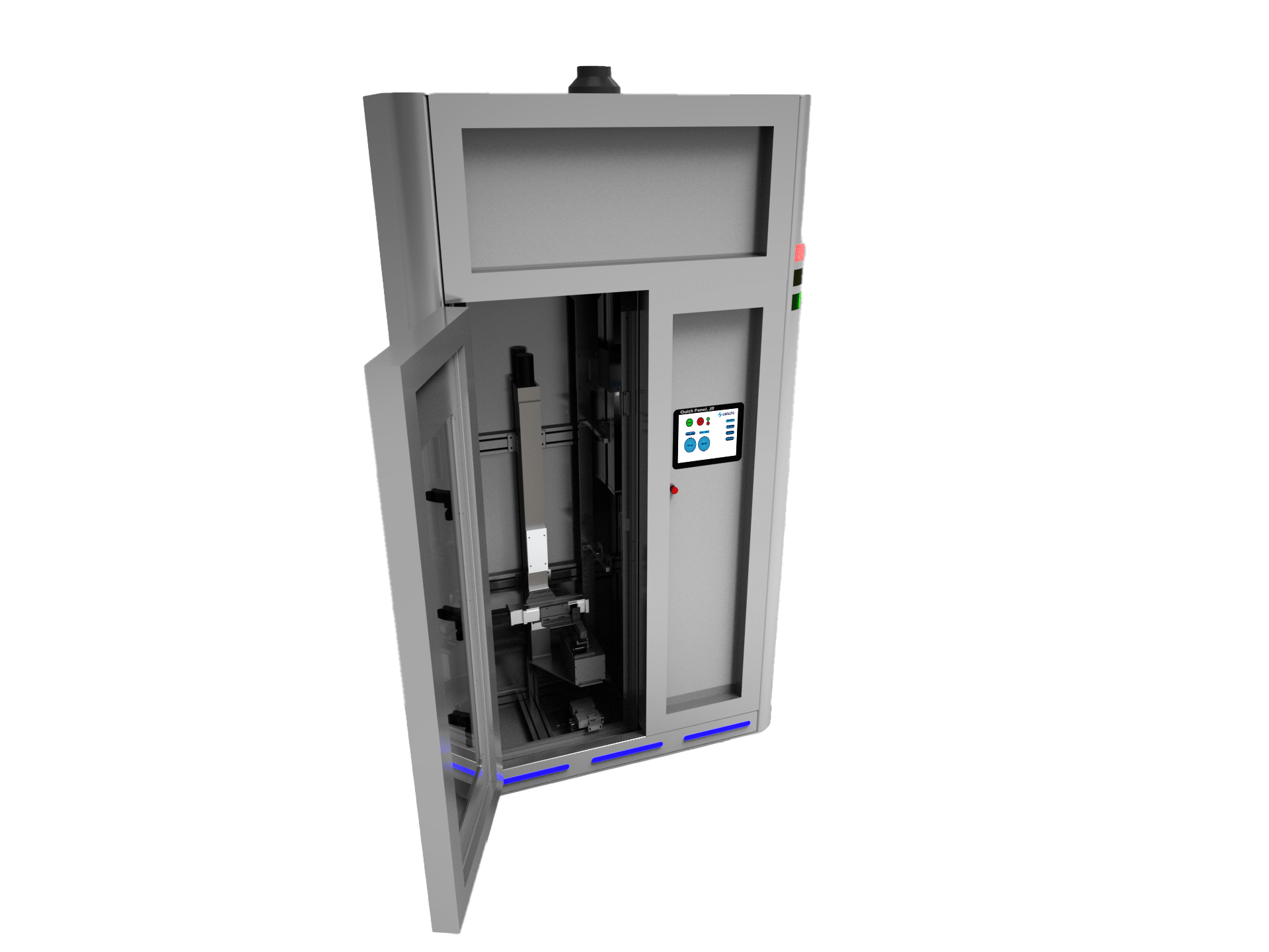

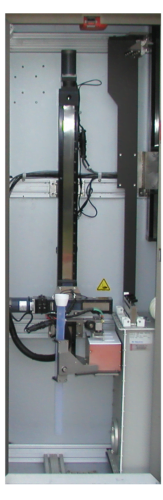

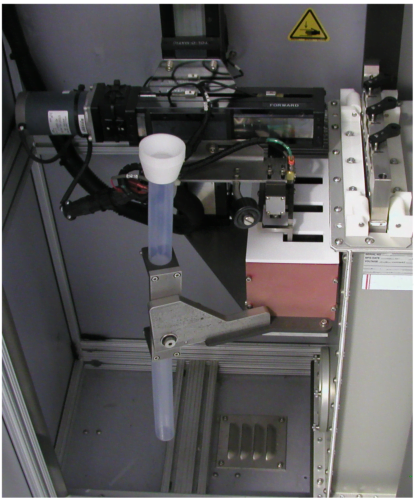

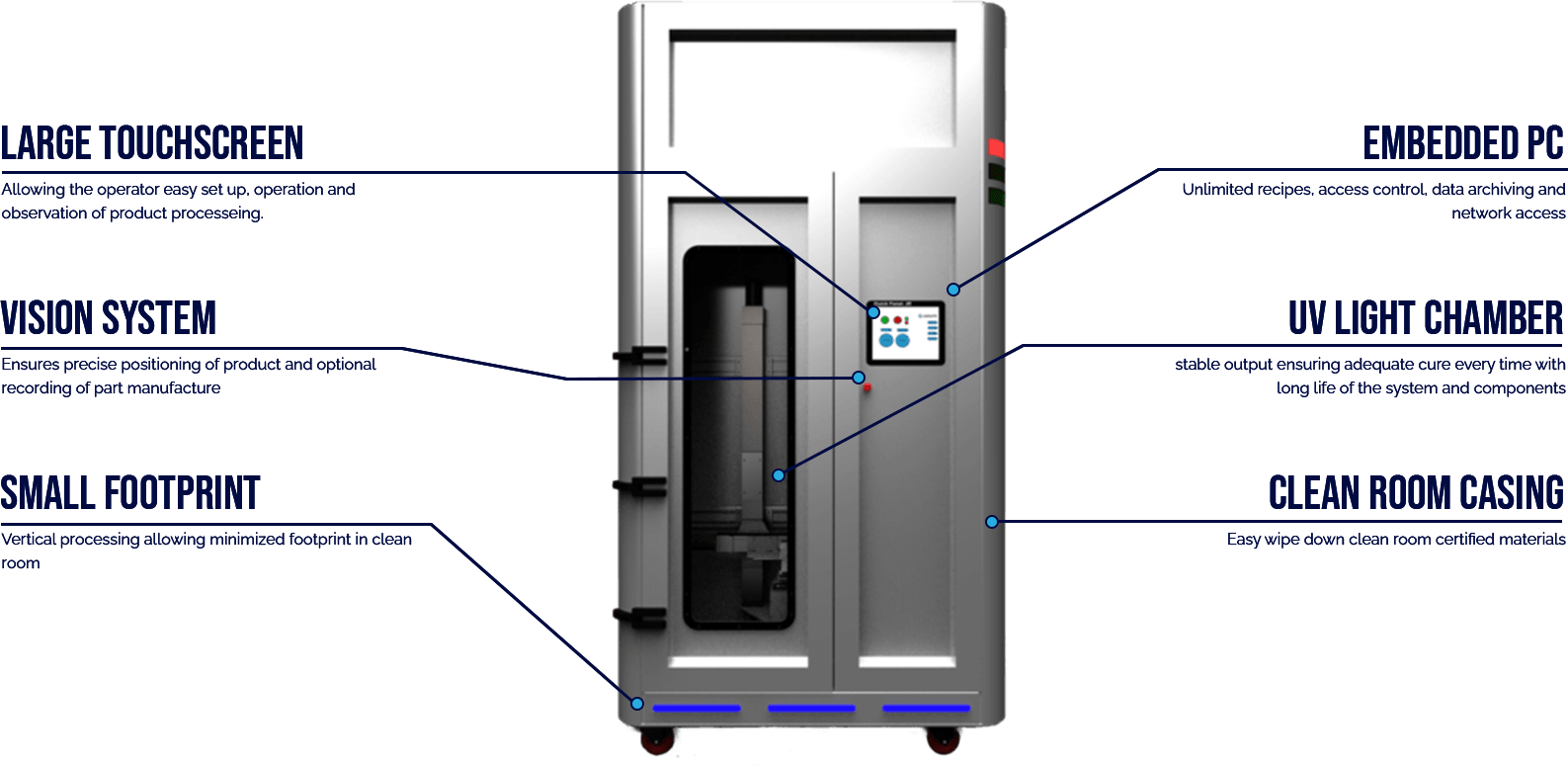

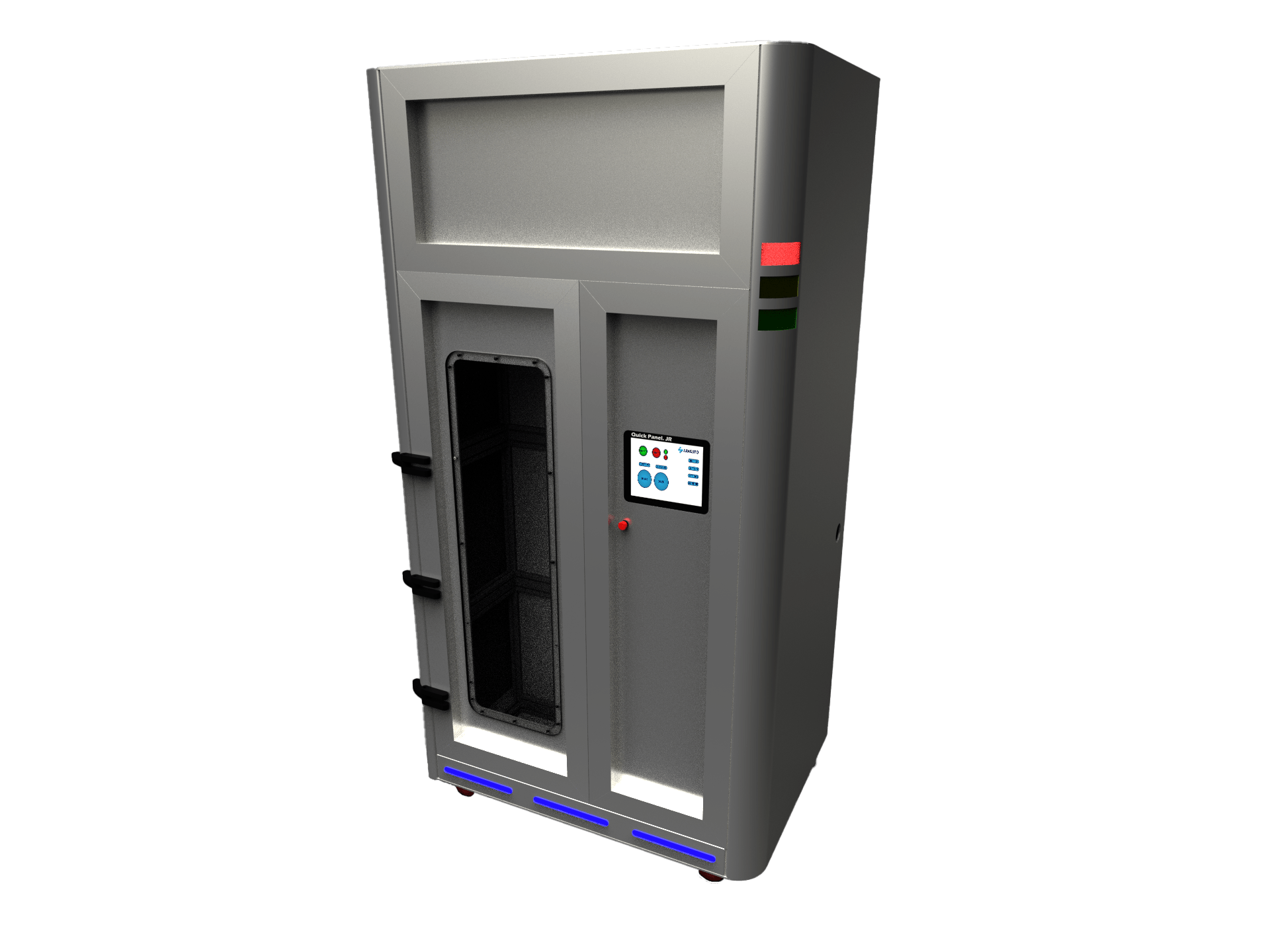

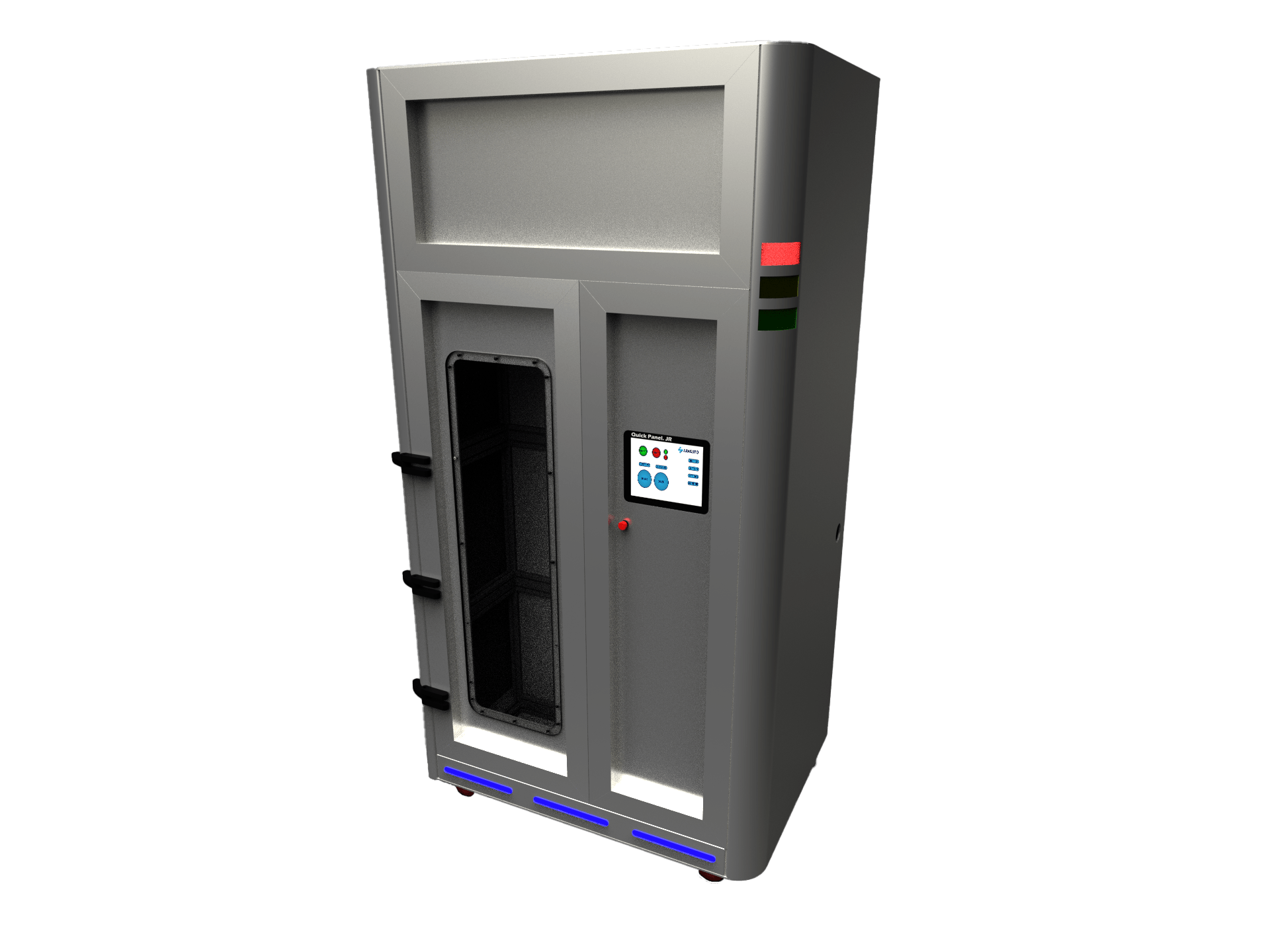

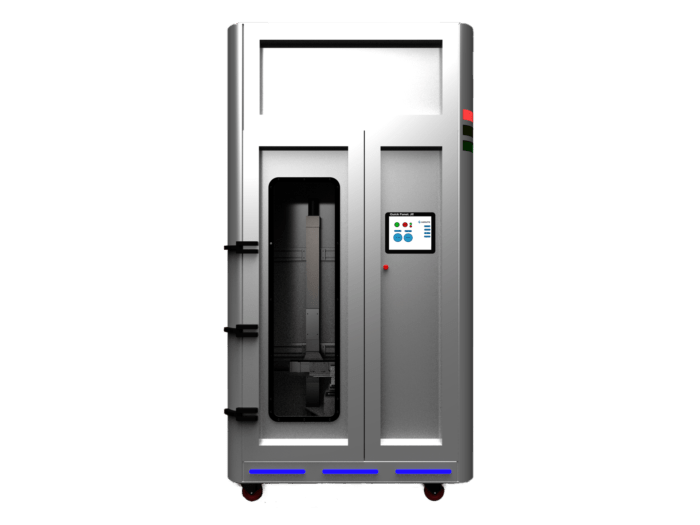

SAVASTO manufactures a standardized catheter coating machine that applies a hydrophilic coating and UV cures the catheter. The machine is manually loaded with catheters, the machine then lowers the catheters into the preparatory solution. The machine has a built in UV oven, the catheters are lowered into the oven and cured. The machine is then manually off loaded.

Machine Features

The Catheter Coating Machine is designed for the coating and curing of catheters (aortic, venous, neurological, guidewire):

Catheter Hydrocoater features:

•Automatic sample clamping

•Variety of catheter lengths

•No programming language involved and no programming experience required

•Four types of programs (manual, statistic, dynamic, multi-steps combining static)

•Color and large embedded touchscreen monitor

•Store multiple programs

•Operating Air Pressure 4bar/58 psi

•Power Requirement 280V -:60Hz: 3PH: 30A

The best in Catheter Manufacturing

With SAVASTO equipment customer catheter manufacturing achieves the quality and volume required to be successful.

Hydrophilic Coating

The coating process can vary but recipes can consist of primer and top-coat solution which is UV cured to the surface, the coating forming adequate adhesion with the catheter polymers (nylons, Pebax and TPU grades of polymer).

Hydrophilic coating, or HC coating, is a surface level coating applied to catheters to enhance trackability by reducing the surface friction.

The increased lubricity provided by HC coatings allows the catheter shaft to target complex areas in the body. Tissue irritation and damage is reduced while patient outcome can be enhanced.

Ultra Violet (UV) Curing

Catheters usually need pretreatment, such as plasma surface-treaters, for adequate coating. The catheter coating is applied via dip coating and then the catheter is UV cured in a stationary mode. A typical UV curing process for catheter coatings takes from 10-40 seconds or more.

Products

SAVASTO products deliver state of the art medical manufacturing technologies ready for turn-key operations out of the box

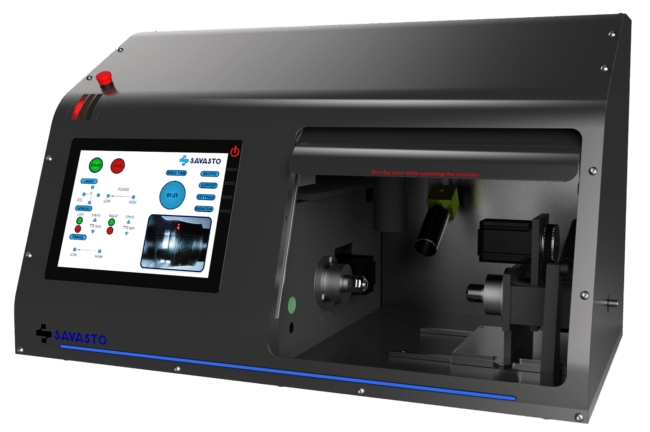

Catheter Bonding Machine

A true turnkey plug-and-play laser bonding and welding system

Catheter Coating Machine

Industry leading Catheter Coat & Cure with UV Curing

Contact Us

Interested in our products? Fill in the form below and we will get in touch with you.

Phone: +1 (747) 202-9147