Benefits of Laser Bonding in Catheter Manufacturing

Laser bonding has been gaining popularity as a technique for manufacturing catheters due to its many benefits over traditional bonding methods. Laser bonding allows for stronger and more precise bonds to be formed, resulting in catheters that are more durable and effective.

Stronger Bonds

One of the major benefits of using laser bonding for catheter manufacturing is that it allows for the creation of bonds that are much stronger than those formed using traditional methods. This is because laser bonding creates bonds at the molecular level, resulting in a much tighter and more secure connection between the materials being bonded. This means that laser-bonded catheters are less likely to break or become damaged during use, making them more reliable and effective for patients.

Precise Bonds

Another benefit of laser bonding is that it allows for more precise bonds to be formed. This is because the laser can be focused and controlled with great accuracy, allowing manufacturers to create bonds that are exactly the right size and shape for their intended purpose. This precision is especially important in the manufacturing of catheters, as it allows for the creation of catheters that are tailored to fit the specific needs of individual patients.

Faster & More Efficient

In addition to being stronger and more precise, laser bonding is also a faster and more efficient method of bonding compared to traditional methods. This means that manufacturers can produce catheters more quickly and at a lower cost, making them more accessible and affordable for patients.

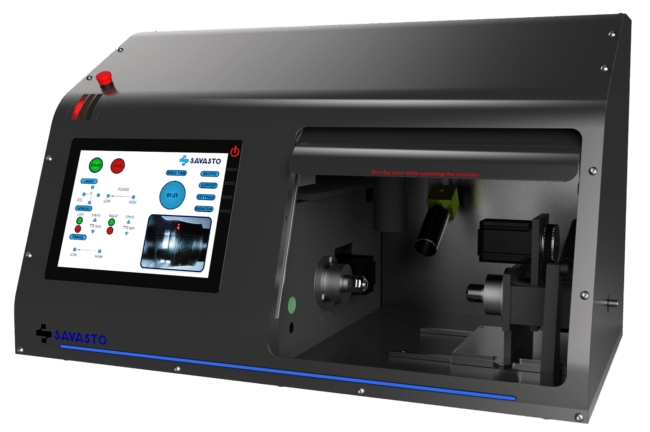

SAVASTO manufactures a standardized machine that bonds various catheter materials using a laser. It is a true turnkey plug-and-play laser bonding and welding system. The Catheter Laser Bonding Machine design is patented and is proprietary technology of SAVASTO, and is available to our clients in the medical device industry.

Medical balloon catheters are critical medical devices delivering life saving solutions to millions of patients every year. Due to the mission criticality of the device manufacturing requires quality and precision. Our Catheter Laser Bonding Machines create, high-precision and dependable balloon bonds.

Our Catheter Laser Bonding Machine provides advantages over traditional bonding methods including adhesive, hot air, and RF due to its superior performance through precise and consistent laser bonding and welding.

Overall, the use of laser bonding for catheter manufacturing has many benefits. It allows for the creation of stronger, more precise, and more durable catheters, and is a faster and more efficient method of bonding compared to traditional techniques. As a result, laser bonding is likely to become an increasingly popular method for manufacturing catheters in the future.

Contact us +1 (747) 202-9147 or visit savasto.com https://savasto.com/catheter-bonding-machine-3/